About MST Corporation:

Welcome to MST Corporation

MST Corporation is an International Leader in Manufacturing, Restoration, Value Added Engineering, Replacement Parts Design and Manufacturing, and Reverse Engineering for Continuous Process Industries, including: Mining, Food Processing, Biofuel, Paper Manufacturing, Paper Recycling, Chemical Processing, and many others.

We offer:

- CNC/CAD/CAM Machining and Design.

- High Technology Welding and Fabrication Services.

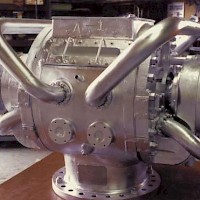

- MST-Bauer High Pressure Rotary Feeders, with our Patented Fast Break-in, Seal and Longer Wear Life Features.

- MST is the Current-Original OEM Bauer High-Pressure Rotary Feeder Manufacturer, providing Rebuilding, Upgrades, and New Replacement High-Pressure Plug Screw Feeders Valves.

- CNC Drilled Plates for all Applications.

- Paper Recycling Extraction Plates, New and Restored.

- Pulper Rotors and Specialty Rotors.

- Our Legendary Exclusive Industrial Ceramilox® Hard Coating, used on Packing Sleeves and Pump Wear Surfaces.

- Precision Reverse Engineering and Manufacture of Industrial Replacement Parts.

- Root Cause Analysis and Upgrade Services.

- MST can work with all Steels: Stainless, Super Alloy and Hardfacing Steels are our Specialty.

About Us - MST Corporation

Who We Are:

In 1968 the founder of MST Corporation began his career in process equipment design, raw material process technology, and upgrade and services manufacturing, principally oriented toward pulp and paper, mining systems and nuclear welding processes. His career activities expanded to include aerospace, nuclear, metallurgical, welding, metalizing, and process engineering technologies as they fit into and benefit machinery and components used for continuous process industries and advanced technology research and development.

In 1981, MST was founded based on the rapidly growing field of material science technology, hence the MST acronym in the company name.

Our Mission:

Our mission is to provide high quality, value-added manufacturing and services for critical machinery and parts used in the manufacture of pulp and paper, paper recycling and related continuous process industries.

Common sense dictates that our customers have the better technical information for making important purchase decisions. MST has an obligation to explain how our value-added manufacturing and services improve mechanical reliability and save you money based on a sound, strong and valid scientific underpinnings—up to date facts. The work MST does is based on sound principles: advanced knowledge of applied physics and process technologies that we can logically support and put in plain words to our customers.

MST strives to always be able to serve our customers on the bases of the most current applied physics involved in the various disciplines that make up modern process technology. We incorporate these technologies into our manufacturing and services. Our advanced process technologies are used to provide the quality products and services essential to our customers' needs.

Business Conduct:

None of the above would have proper meaning absent authentic integrity. MST has always conducted business based on the idea that, in business, there truly are self-evident principles of conduct.

We strive to have our business conduct espouse the absolute imperative that business, in order to be meaningful to each party involved, requires that there be shared relationships founded on the highest standards of honesty and integrity. That is, shared relationships, which cultivates heartfelt mutual respect. For this to happen, integrity must be openly evident and an integral part of what we do and how we conduct our transactions with our valued customers and suppliers.

We sincerely thank you for the opportunity to serve your needs and requests.

Products and Services Master List

- CNC/CAD/CAM MACHINING & DESIGN

- HIGH TECHNOLOGY WELDING SERVICES

- OEM-BAUER & MST-BAUER HIGH-PRESSURE ROTARY FEEDER VALVES

- MST-Bauer CenterSeal® High-Pressure Rotary Feeder Valve Technology News & Update

- HIGH-PRESSURE PLUG SCREW FEEDERS

- EXTRACTION PLATES, SCREENS, DRILLED PLATES

- PULPER ROTORS & SPECIALTY ROTORS

- CERAMILOX® HARD COATING PACKING SLEEVES

- REPLACEMENT PARTS

- SPECIAL SERVICES

- CNC/CAD/CAM MACHINING & DESIGN

- Manufacturing New Extraction Plates

- Restoration & Repair of Extraction Plates & Screens

- Manufacturing & Restoration of Drilled Plates

- HIGH TECHNOLOGY WELDING SERVICES

- High Alloy Technology is our Specialty

- Custom Fabrications

- Hardfacing Technology

- Buildup & Restoration

- HIGH PRESSURE ROTARY FEEDER VALVES

- Bauer Valve Manufacturing & Restoration

- MST-Bauer CenterSeal® High-Pressure Rotary Feeder Valve Technology News & Update

- ESCO & LE Valve Manufacture & Restoration

- HIGH-PRESSURE ROTARY SCREW FEEDERS

- Complete Restoration & New Replacement Parts Services

- Reverse Engineering; Custom Design, Retrofit & Manufacturing

- PULPER ROTORS & SPECIALTY ROTORS

- Rotor Remanufacturing Services

- Rotor Wear Technology, Redesign & Retrofit Services

- PACKING & WEAR SLEEVES

- Ceramilox® Hard Coat Surface Science

- Replacement Packing Sleeves & Super Hard Coated Sleeves

- PARTS – REPLACEMENT, CUSTOM, REMANUFACTURING & RESTORATION

- Replacement Parts Reverse Engineering Services

- Replacement Parts Manufacturing

- Replacement Parts Restoration & Value Added Engineering

- PUMPS - Replacement Parts & Restoration

- CONVEYING - Manufacturing, Restoration, Value Added Engineering

- HIGH ALLOY-EXOTIC ALLOY MANUFACTURE, RESTORATION & REPLACEMENT PARTS - Stainless Steel, Super Austenitic, Super Alloys, Titanium

- POWER & RECOVERY

- GENERAL MACHINERY - Restoration, Retrofitting & Re-manufacturing of Process Machinery

- SPECIAL SERVICES

- Failure Analysis with Option Recommendations

- Root Cause Analysis

- Metallurgical Analysis

- Reverse Engineering, Custom Manufacturing, Restoration & Retrofit